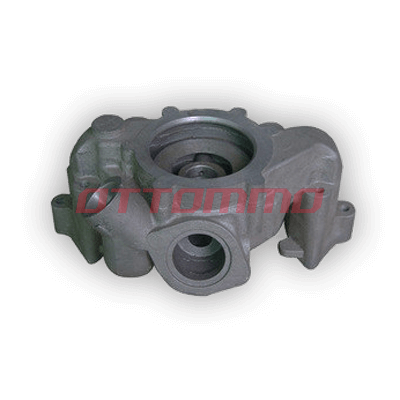

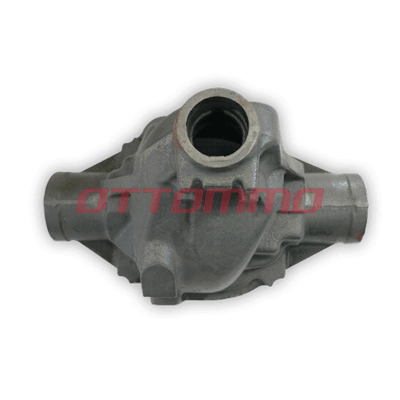

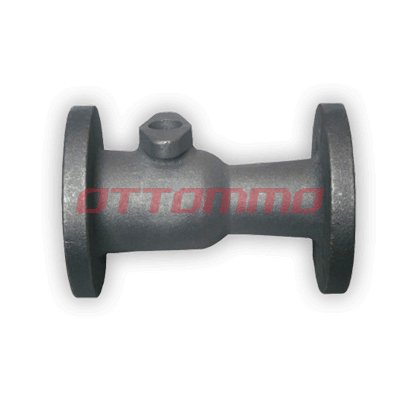

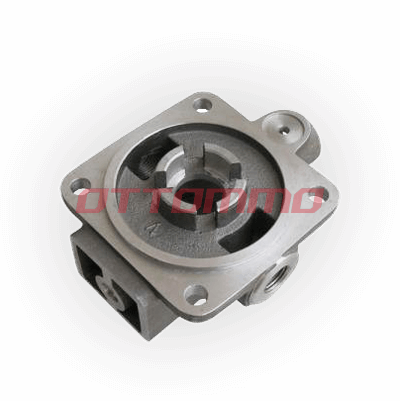

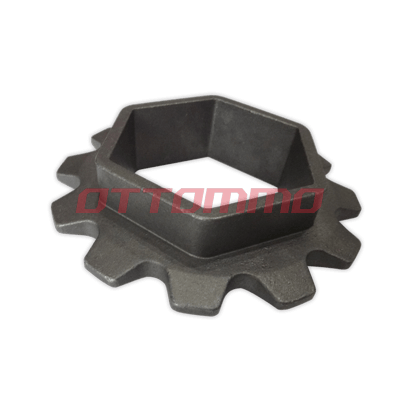

China Iron Casting Foundry

OTTOMMO Casting has been dedicated to deliver high-quality iron parts. Our iron casting foundry offers you sand casting and investment casting options.

Iron Casting Process Options

- Sand Casting is the most common process for making iron parts. Normally, these parts are big and high-tolerance. Besides, they do not require a good surface finish. If you are looking for a part like this, contact us and get the casting with the low cost.

- Investment casting process is also available in our foundry for making iron parts. Most iron foundries in China do not offer this option. A lot of iron parts in the market still need a good surface finish with less porosity. So, OTTOMMO Casting provides you both water glass and silica sol investment casting processes. The differences between these processes are the surface roughness and price.

OTTOMMO Casting offers you various 300/400/PH series stainless steel casting parts with investment casting process and sand casting process in China.

OTTOMMO Casting is your trustworthy carbon steel casting manufacture here in China. Our foundry makes various carbon steel casting grades available to you.

OTTOMMO Casting focus on providing you good aluminum casting ideas. Many aluminum alloys for your to choose. Many casting processes to fulfill your parts.

OTTOMMO casting makes copper, bronze and brass casting available to you. We are capable to provide you sand casting, lost wax and die casting processes.

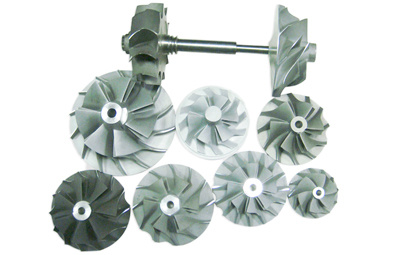

OTTOMMO Casting is your best nickel alloy casting company. Our specialties are super alloy turbo wheel and high nickel based casting by vacuum casting process.

Ductile Iron and Grey Iron Casting

Our foundry poured ductile iron more often than grey iron. Ductile iron has higher strength and ductile. Therefore, this makes the ductile iron parts widely used in the automobile and pump industry. However, we also got a lot of inquires of grey iron parts. Typically, this comes with a machining request.