OTTOMMO Die Casting Plant

This casting method refers to force the molten metal under high pressure into reusable metal dies. Then, metal solidifies rapidly and we get the raw casting by separating dies. This process is a quick and cost-effective method for high volume geometrically complex metal parts. In 2010, OTTOMMO Casting established the die casting plant as our joint venture. We aim to provide you high-quality non-ferrous casting parts. Besides, we are capable of full in-house CNC machine, surface treatment and assembly.

Unique Die Casting Process

We learnt from past 7 years. Most inquires of die cast parts required machining and surface treatment. Therefore, this makes OTTOMMO die casting unique for you. From tooling/mold making to surface treatment and assembly, we handle everything for you in house.

Tooling/mold Design - STEP 1

Tooling/mold Making - STEP 2

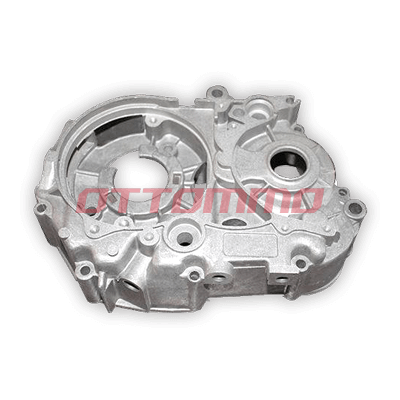

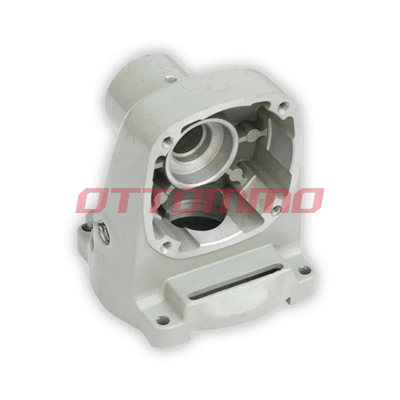

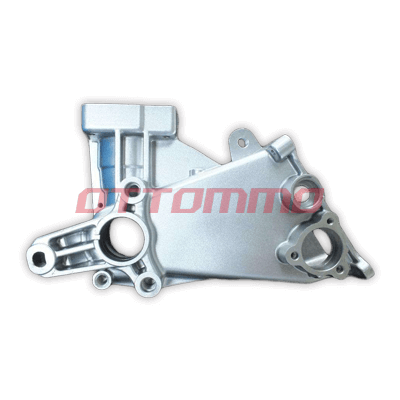

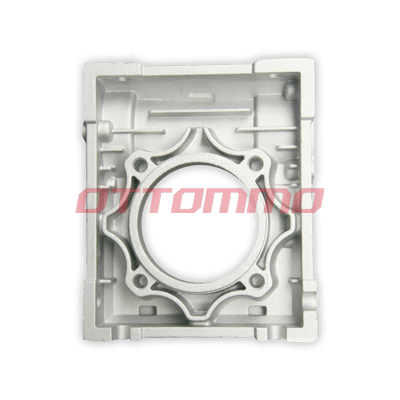

Die Cast Parts - STEP 3

Casting Cleaning - STEP 4

Parts Machining - STEP 5

Surface Treatment - STEP 6

OTTOMMO Die Casting Capabilities

We have three shops in this plant: die cast shop, tooling/mold shop and finishing/assembly shop. Contact us today and you do not need to ask quotes from different places for a single part.

Die Cast Shop

180T, 280T, 400T, 500T, 630T die casting machine total 20 sets

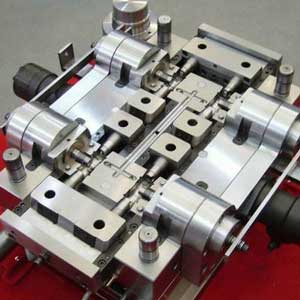

Tooling/mold Shop

Cutting machine, EDM machine, milling machine, Tapping Machine, Lathe, drilling total 50 sets

Finishing/assembly shop

Painting, Anodizing, Powder Coating, Plating, Sanding, Buffing and Polishing

Aluminum Die Casting

A380, A384, A386 and A390 are most frequently used material here to die cast parts. This alloy maintains high operational temperatures and excellent corrosion resistance. Besides, it is very light but has pretty decent strength and hardness. Even though this alloy has many options for surface treatment, A380 is not good for anodizing. We are also open to other aluminum alloys and processes per your request. Contact us today to get the quote.