Advantages and disadvantages of investment casting

Advantages of investment casting

- Complex shapes which are difficult by any other method are possible;

- Very close tolerances and excellence surface finish can be obtained;

- Ready for use with little or no machining required;

- Almost any metal can be cast;

- No parting lines

- Capable of large shape so that lower cost

Disadvantages of investment casting

- Time consuming process

- Expensive labor cost

- Limited casting size

- Occasional defects

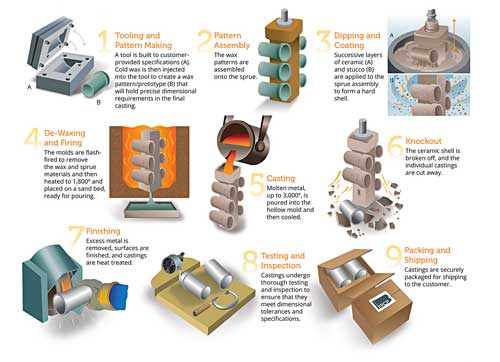

Precision Investment casting (Lost Wax Casting)

There are two main processes of investment casting water glass process & silica sol process. The water glass process is suitable for large parts of carbon steel, alloy steel, ductile iron & grey iron. The silica sol process is for small parts of stainless steel casting (ss304, ss316, ss316l). We can offer you both of these processes as your requirements, but we focus on silica sol process casting business as we focus on high-level markets all over the world.

Investment Casting Applications

Aerospace, industrial gas turbine, medical, automotive, military, sports recreation.

About us and this blog

OTTOMMO Casting is a precision casting foundry in China. We have been dedicated to providing cheap but quality castings for years all over the world.

Request a free quote

OTTOMMO Casting provides various casting process and brings many unique benefits to our customers. We have built three casting plants in the past 15 years in order to offer you more casting solutions.