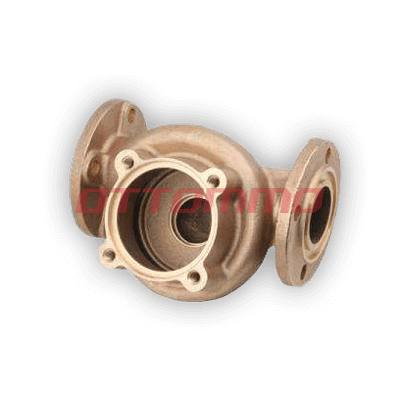

Brass Valve Casting

Casting Alloy: In most cases, we poured Tin bronze casting, aluminum bronze casting, silicon bronze casting and yellow brass. The grades will be C836, C857, C875 and C954.

Casting process: Brass Sand casting. Sand casting and investment casting are two basic processes for us to make the brass parts for you. Besides, we are also open to die casting, centrifugal casting and forging processes. We deliver the parts and service exactly based on customers’ needs.

Casting Tolerance: CT9-CT11

Machining Tolerance: IT4-IT12

Investment Casting Process

As we started as an investment casting foundry, we know details of this metal-forming technique. Investment casting is also known as lost wax casting. Basically, it refers to make a wax pattern formed with a ceramic. Then, melting the wax makes the ceramic empty. Eventually we get the casting after pouring the metal into the ceramic. OTTOMMO Casting continues to improving our process and utilizing the newest technology available in our industry.

Die Casting Process

Die casting refers to force the molten metal under high pressure into reusable metal dies. Then, we get the raw casting after metal solidifies rapidly. This process is a quick and cost-effective method for high volume geometrically complex parts. In 2010, OTTOMMO Casting established the die casting plant as our joint venture. We aim to provide you high-quality non-ferrous casting parts. Besides, we are capable of full in-house CNC machine, surface treatment and assembly.

Sand Casting Process

As a cost-efficient casting method, sand casting is still popular in China. Basically, it refers to make a sand mold with cavity of casting shape inside. Then, we get the casing after pouring metal into the cavity and metal solidifies. In OTTOMMO sand casting plant, we have both manual and semi-automatic sand casting production lines for castings with various size, weight and geometries. Besides, our sand casting capacity ranges from 3 lbs. to 2500 lbs.